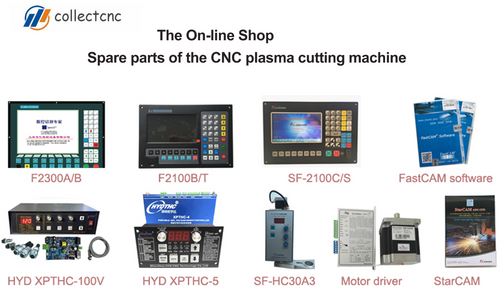

SHANGHAI FANGLING FLMC-F2300B V5.0 CNC Plasma Cutting Controller

SHANGHAI FANGLING FLMC-F2300B V5.0 CNC Plasma Cutting Controller

Couldn't load pickup availability

High stability FLMC-F2300B cnc plasma cutting controller

FLMC-F2300B Model now have updated to F2300B V5.0 version, the outlook as follow

Model: FLMC-F2300B V5.0 ( Just ship the New V5.0 model)

Made in china.

Low cost CNC Plasma cutting machine used CNC controller.

Work Condition

Working Temperature, 0℃~50℃. Relative Humidity, 5~95%.

Operation Voltage: DC +24V.

The controller should be installed in a cab which can provide protection from powder.

The controller would be better used in the situation without high voltage radiation.

Configuration

Monitor: 10.4 inch 800*480, high definition 16 million colors and high brightness LCD

Memory: 64M SDRAM

Program space available for user: 256M electronic hard disk

System master frequency: 400MHz

USB: USB 1.1 front interface, at least 16GB U disk supportable

Keyboard: electronic PCB foil keyboard

Chassis: full-steel structure completely shielded which defends electromagnetic radiation, interference and static electricity

System Information

45 categories different graphics (including grid pattern), chip part and hole part are alternative.

Graphics have some operations such as Proportion, Rotate, Mirror.

Graphics can be arrayed in matrix, interaction, stacked modes

According to plate thickness, the cutting speed is automatically restricted by a speed limit in the corner, effectively preventing over burn.

metric system/ imperia system switch

Steel plate can be adjusted according to any steel side.

Coordinate system can be customized to support the two-dimensional coordinates of all eight kinds.

All input and output port type and the number can be customized (normally open or normally closed)

system and parameters backup, update system online

Chinese / English (including Japanese, Russian, French and other languages )file system and menu can be switched only by one key.

select row and column manually.

support edge cutting and offset cutting.

Automatically memorize the working situation and the last cutting point when power off.

Dynamic/static illustration of the process, graphics zoom in / out, dynamically tracking cut-off point under zooming state.

support artgrave, TYPEIII, PM2000 cam software

set up different administration authority to and the corresponding password to safeguard the interests of managers.

Technical Indicator

1) Control Axis: 2 axis linkage(3 axis customizable)

2) Control accuracy: +/-0.001mm

3) Coordinate range: +/- 99999.99mm

4) Max pulses: 200 kHz. Max speed: 15,000 mm/m

5) Max lines of code: 150,000lines

6) Max size of single code file: 4M

7) Time resolution: 10ms

8) Working Voltage: DC +24V direct-current power input, power > 80W。

9) Working Temperature: -10℃~+60℃. Relative Humidity, 0~95%.

10) Max power of drive arc THC motor: 45W (suitable for models with “T”). if need more power, can select maximum value: 200W.

System Interface

a) 15 pins SMA Male interface of 2 axes of motor drive.

b) 25 pins SMA Female interface of 16 channels optoelectronic isolation output ports max back flow current 300mA.

c) 25 pins SMA Male interface of 16 channels optoelectronic isolation input ports,max output current 300mA.

d) USB interface on the front panel, for the convenience of transmitting cutting code.

e) Extend IO input/output ports, PWM input ports, analog input ports.

The following three interfaces are only suitable for models with “T”:

f) Selection of partial pressure proportion of arc input: 1:50 or 1:100

g) 5 cores THC motor output and limit input ports.

h) 7 cores arc pressure and position input port, arcing signal output port.

F2300 A/B/T Hardware Configuration

1. Monitor: 10.4 inch 800*600, high definition 16 million colors and high brightness LCD

2. Memory: 64M SDRAM

3. Program space available for user: 256M electronic hard disk

4. System master frequency: 400MHz

5. USB: USB 1.1 front interface, at least 16GB U disk supportable

6. Keyboard: electronic PCB foil keyboard

7. Chassis: full-steel structure completely shielded which defends electromagnetic radiation, interference and static electricity